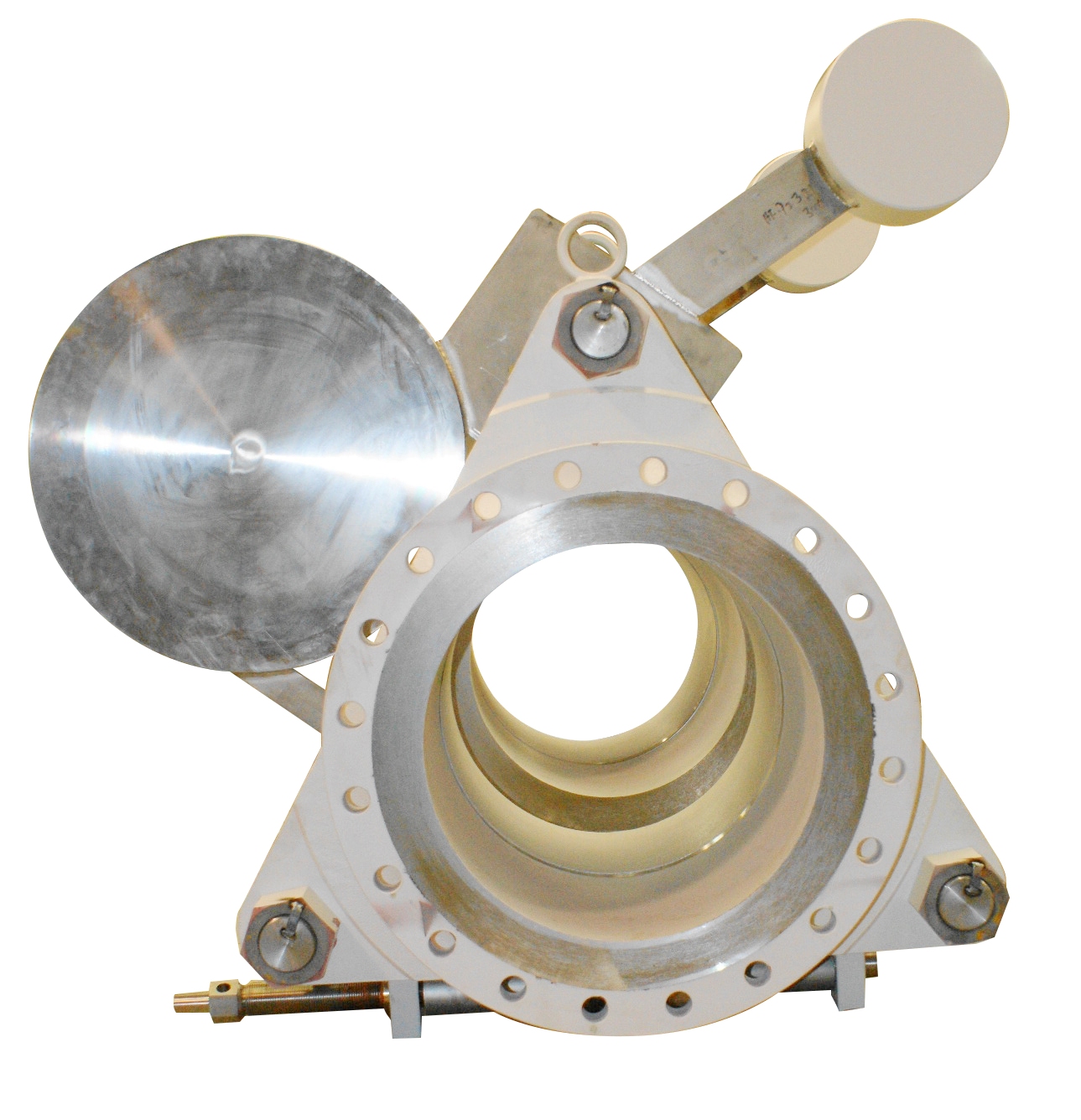

Cam-Set

The Cam-Set (Model 81 FC) is a swing type of quick acting line blind. It has a three bolt design and a triangular body. It is appropriate for applications that require fast blinding turnaround and that do not exceed 1500# pressure class. It can be made as a standard design up to 48 inches (DN 1200).

20 inch line blind with Counterweight

20 inch line blind with Counterweight Cam-Set Operation

Thanks to its revolutionary Cam design the spectacle plate can be locked into place or released in seconds. The plate can then be rotated or swung from left to right with ease. For larger size lines 12 inches and above the Cam-Set can be equipped with a counterweight, making plate position changing even easier.

- Man

Safe – 100% positive isolation

- Can be operated in less than 30 seconds

- Available in sizes up to 48 inches and ASME 1500#

- Non line spreading design

- Seals not affected by piping misalignment

- Simple operation – one person, one side, no bolts need to be removed

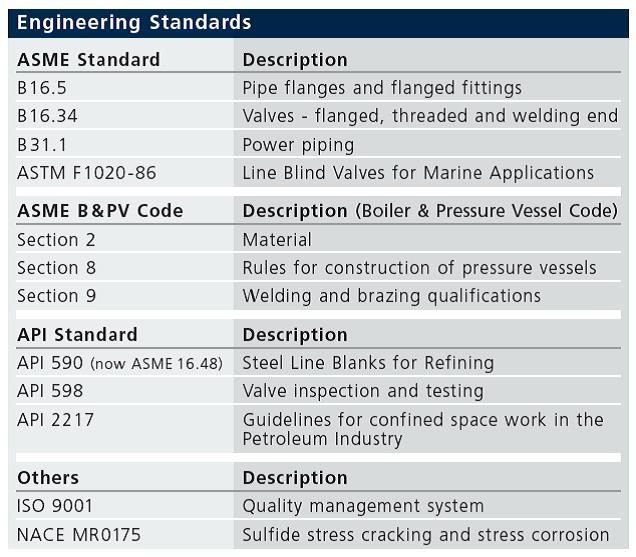

- Conforms to or exceeds many safety and engineering standards

A broad range of sealing rings to match the specific medium and operating conditions including the most common – Viton, Kalrez, Aflas, EPR/EPDM, Kal-F etc.

A broad range of sealing rings to match the specific medium and operating conditions including the most common – Viton, Kalrez, Aflas, EPR/EPDM, Kal-F etc.- Stem and dust covers for powder applications or dusty operating environments

- Lock out devices

- Pneumatic or manual actuation

- Filter, rupture disc or sieve integration in the spectacle plate

- Drain, vent and purge connections

- Special anti corrosive or medium driven coatings or linings (such as Sermetal, Epoxy, PFA or ceramics)

- Reinforced designs for challenging operating environments

The below dimensions are for the standard Cam-Set sizes:

Purpose

The primary Purpose of a swinging line blind is to completely close off the downstream portion of a pipeline in a quick and safe manner. Generic uses are:

- To guarantee safe operating conditions for maintenance procedures

- To enable quick line shut down in emergency circumstances

- To help prevent product cross contaminations in tank farms or ocean going tankers

- To avoid pollution due to valve leakage