Engineered for Safety

Fetterolf Line Blinds are designed and manufactured to a broad set of industry standards.

|  |  |

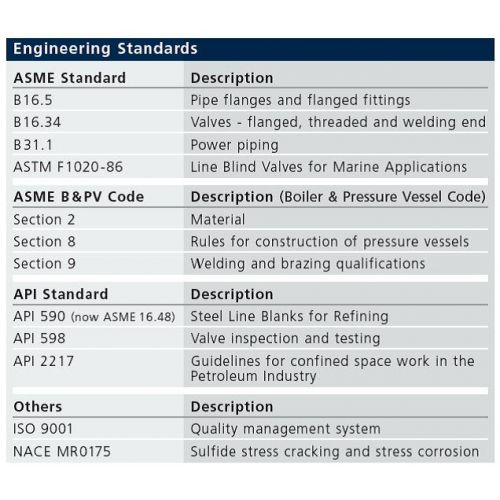

As line blinds are piping components and from a technical perspective not strictly valves, it is important to ensure a strict set of guidelines for their development. The engineering standards that we apply are outlined below. In addition all new designs are proven by finite element analysis (FEA).

Engineering Standards for fast acting Line Blinds

The most important standard used for designing and manufacturing the Cam-Set and Cam-Slide Line Blind is the ASME Boiler & Pressure Vessel Code - Section 2 outlines the parameters for material selection, whilst section VIII sets rules for construction of pressure vessels.For a line blind with flanges, ASME B 16.5 and ASME B 16.34 are followed. The thickness of the steel blanking plate is defined by API 590 (ASME 16.48)

If the blind is to be used in Marine applications or on a FPSO or an Ocean Tanker ASTM F1020-86 is adhered to. Finally all line blinds are stringently tested according to the relevant standard - API 598.

By following all of the above standards, Fetterolf can guarantee that a line blind valve is fit for purpose and safe. 100% positive isolation is achieved without fear of body deflection or incorrect plate or bolt sizing.

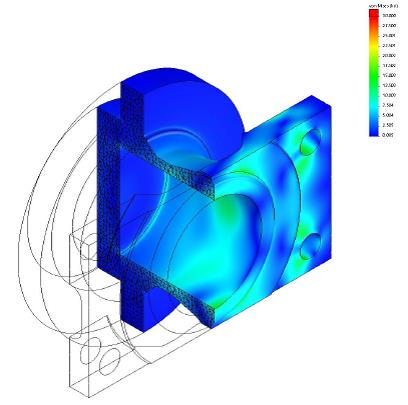

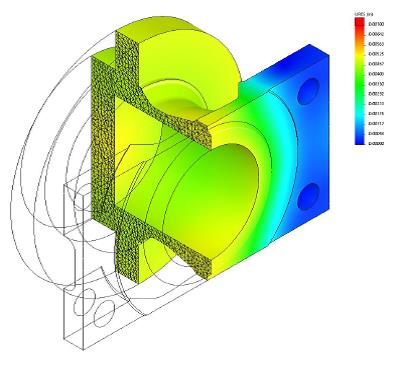

Finite Element Analysis

Finite Element analysis is carried out on every line blind valve size and design in order to ensure that there is no body deflection and that all possible stresses can be managed. Two examples are shown below.

| Stress Distribution | Deflection Analysis |

|  |

Our detailed set of software driven analytical tools enable us to verify new designs particularly for higher pressures or for aspects which a client may wish us to customise.