Choosing the Correct Line Blind Valve

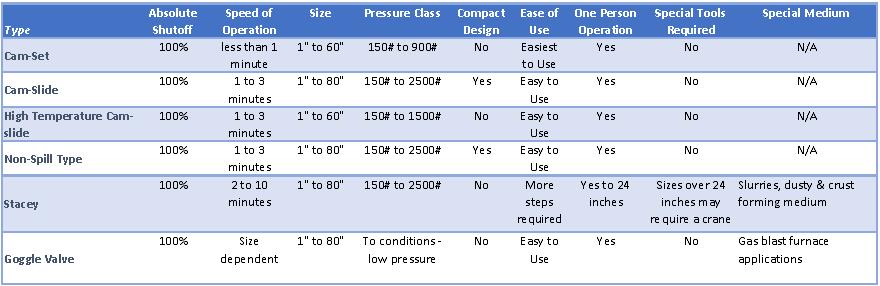

The wide range of line blind valve types available can make it difficult to choose the right one for your application. In this section we discuss the differences between the Swing Type - Cam-Set, the Sliding Type Cam-Slide and the Line Spreading Type - Stacey.

Whether you choose a quick-acting line blind such as the Cam-Set or Cam-Slide or a line spreading type such as the Stacey, the following core attributes are always important:

- 100% positive isolation is guaranteed

- Fast operation

- One man operation

- Conforms to ASME B 16.5 and API 590 as a minimum

Of the three types of line blind valve available, the most common type installed worldwide is the Cam-Set fast line blind (Swing Type). However, there are some important differences. The differences are primarily a question of how easy, how fast or how convenient a line blind is to operate. The operating environment can also play a role. Certain applications require no spills no matter how small during plate position changing - the Non-Spill Cam-Slide is the ideal line blind valve for this.

Choosing the right type of fast acting line blind valve (Swing, slide or line spreading type) depends on key factors such as speed of operation, available space and application type. A simple decision tree is illustrated below:

Cam-Set - Fast, Safe and Convenient

- Operates in less than 60 seconds

- Up to 60 inches; ASME 150#, 300#, 600# and 900#

- 100% positive isolation

- Swing type

- Options - drain ports, strainer inserts

Cam-Slide - Fast, Safe, and Compact

- Operates in less than 60 to 240 (for large gear operated sizes)

- Up to 60 inches and ASME 150# - 2500#

- Compact designs with reduced face to face dimensions available

- 100% positive isolation

- Sliding type

Stacey - Dependable, Safe, Rugged

- Operate in 2 to 10 minutes (size dependant)

- Up to 60 inches and ASME 150# - 2500#

- Line spreading - crust breaking

- Ideal for slurries and fouling media

Specific Differences

I - Cam-Set - Fast Acting Line Blind - Swing Type

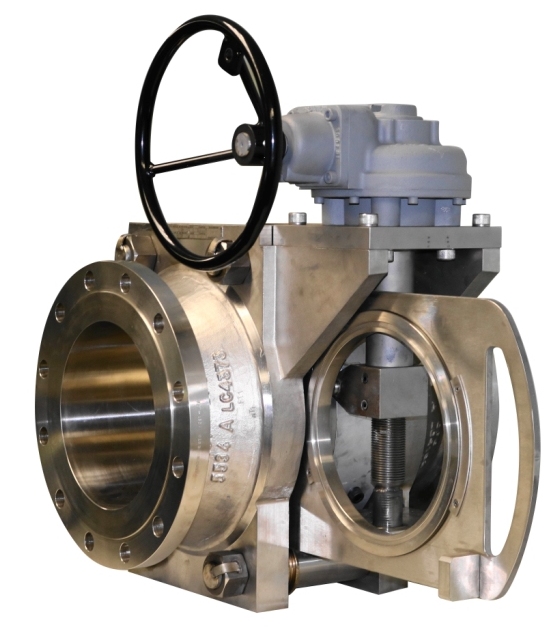

The Cam-Set quick-acting line blind (first picture below on the left) is the all rounder with the best performance with regards to speed and ease of operation. It can be swung in less than 60 seconds even for sizes up to 40 inches (with a counter weight option); by one operator and from one side of the line. Needless to say 100% positive isolation is assured. It is also the most cost effective option of the three types.

| Cam-Set Line Blind (Swing Type) | Cam-Slide Line Blind (Slide Type) | Stacey (Line Spreading Type) |

|  |  |

II - Cam-slide Fast Acting Line Blind - Sliding Type

The Cam-Slide (middle picture above) is similar in design to the Cam-Set except that the plate slides from side to side. This can be an advantage if there is not sufficient space overhead to accommodate the swing arc of the swing type. The Cam-Slide line blind valve can also have shorter face to face dimensions due to its multi body bolt design. This makes it ideal for installations where space is an issue. It is as fast as the Cam-Set in sizes up to 10 inches, but can require 2-5 minutes to operate in larger sizes (12 to 40 inches) as it does not have a counter weight option. It is also the blind of choice for higher pressure classes above ASME 900# class.

III - Stacey Line Spreading Line Blind Valve

The last type is the line spreading type - the Stacey. This blind valve has a different operating mechanism to the Cam-Set and Cam-Slide. It operates via a set of spreader bolts that spread the pipeline in order to create space for the spectacle plate to be swung. We only recommend the Stacey for special applications that benefit from line spreading such as in the cement, alumina and coal industries. In these and other industries where scale formation or dusty and wet solids can prevent the spectacle plate from easily being swung the spreader bolts assist by breaking the encrusted seal. The Stacey can also be used for high temperature applications as a cost effective alternative to the High Temperature Cam-Slide model.