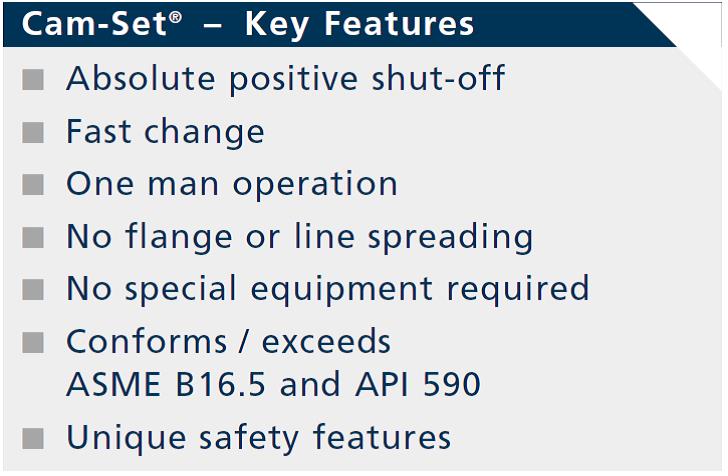

Cost Efficiency

Using Fetterolf Line blind valves can lead to significant cost savings. These cost savings result from:

- Time saving during the blanking process

- Process downtime reduced to a minimum resulting in continued production

- Time and cost saved due to fewer safety related incidents or accidents

Whilst assuring process safety is the most important factor, cost savings add a positive incentive for using the Cam-Set or Cam-Slide

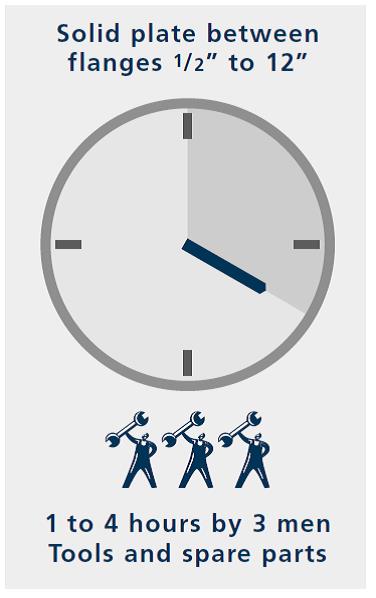

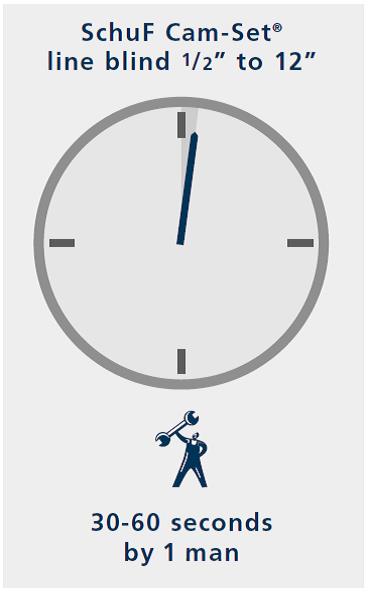

The cost of installing a fast acting blind valve pays for itself in the shortest possible time. The first area of saving is in the new procedure for blinding. Please see the Comparison section below.Traditional line blinding is achieved in eight difficult, labor intensive and time consuming steps compared to three easy actions in as little as 30 seconds with the Cam-Set and Cam-Slide line blind valves.

But our customers tell us that the biggest cost saving result from much shorter outages during routine maintenance. Changing a large spectacle plate in a critical process line could take up to two days - two days of lost or reduced productivity can add up quickly to hundreds of thousands of dollars in product.

Old Procedure with Steel Blanks

- Loosen and remove all

flange bolts

- Insert cheater bars at

several points to spread the line

- 2-3 operatives exert

significant force to achieve line spread

- Allow any media residue to drain out

- Keeping the line spread remove the gaskets & steel blank

- Insert new gasket and reverse blank

- Re-align pipeline

- Insert flange bolts and tighten

New Procedure using the Cam-Set in 3Easy Steps:

- Turn the hand wheel to un-clamp the spectacle plate

- Swing the plate (or counterweight) to the required position

- Turn the hand wheel to re-clamp the spectacle plate

Time Saving Comparison

|  |