Non Spill Line Blind Valve

Certain applications and changing regulatory standards have led to the development of non spill line blinds. The non spill refers to the potential spill that may occur during switching of the blinds from open to close or vice versa. Fetterolf has developed many non spill designs.

Non Spill Line Blind Valve

Non Spill Line Blind Valve Non Spill Design

The non spill design is based on the Cam-Slide product but has a body cover that captures any spills that might happen during plate position switching. The body cover covers the sides and the bottom of the line blind valve. The top remains open in order to move the plate and for safety reasons.

Fetterolf has designed several non spill versions in order to meet the space requirements of your application:

- Double half plate design for areas with limited space

- Single plate design for areas with moderate space and higher security requirements

- Full plate design with gearbox actuation for larger sizes and where space is not limited

Whatever you requirement Fetterolf either has a design or can customize the non spill blind valve.

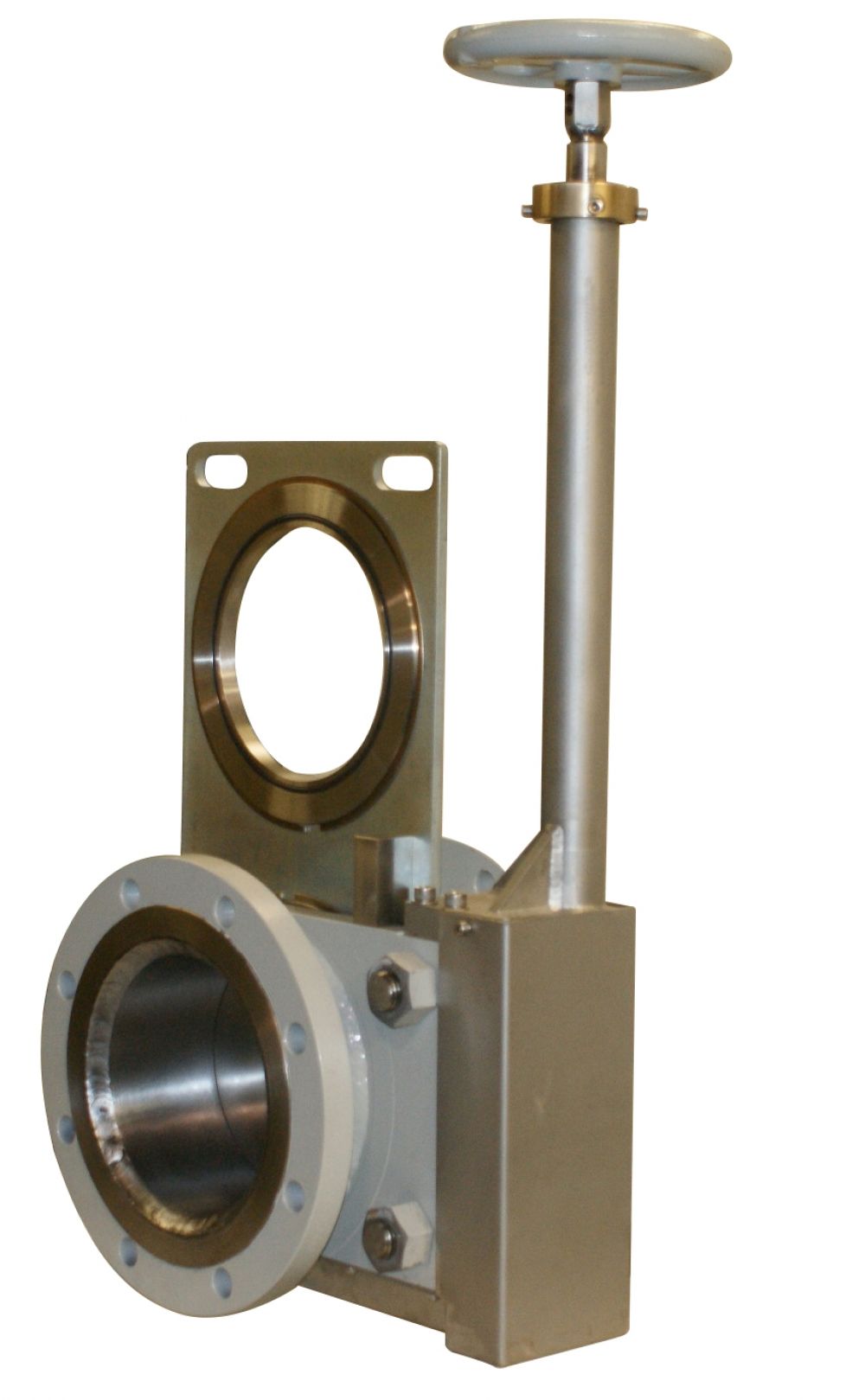

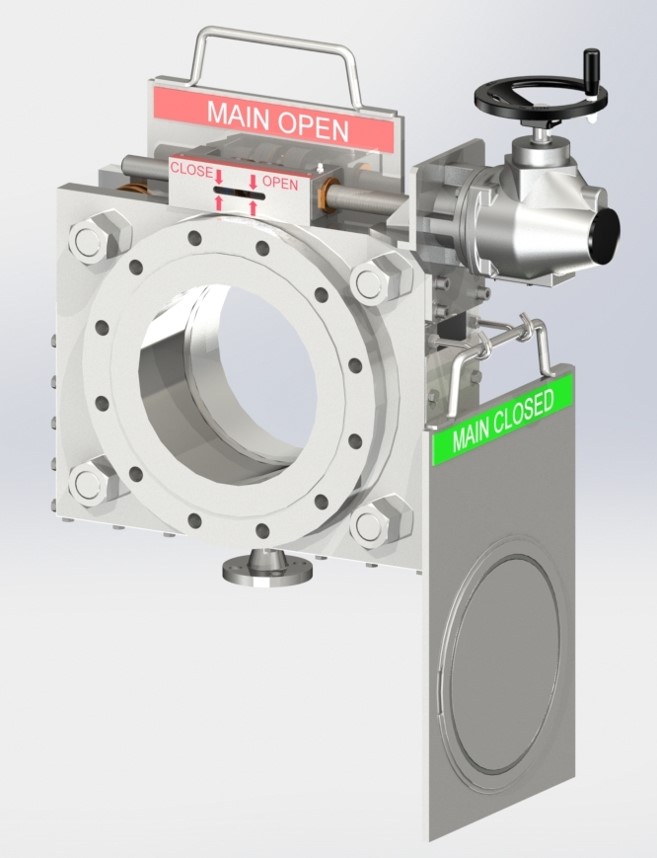

The first design shows the double half plate non-spill line blind design.

This is ideal where space is limited. The body of the blind is reduced as the blind comes with two plates - one for open and one closed (blind position. The face to face dimensions of this type can also be compact. This design has several advantages:

* Clear and visual indication of open or closed

* Fast operation - less than 60 seconds

* Effective non drip by enclosure on all side except the top

* Ease of maintenance

* Safe Operation

* Compact dimensions

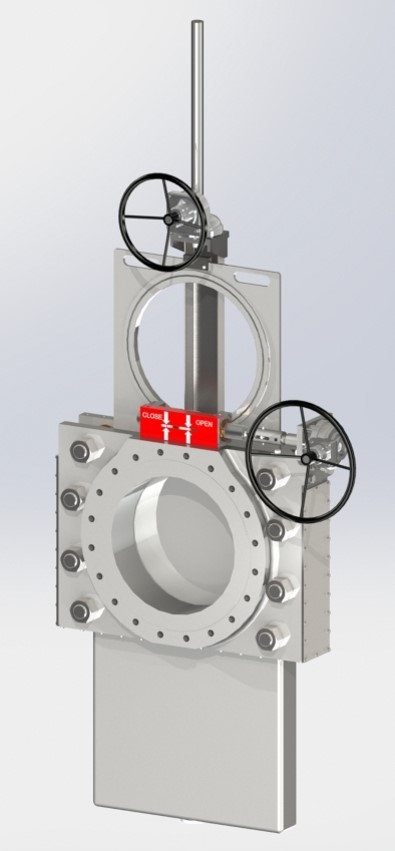

The full plate non spill design is primarily for larger sized (bigger than 10 inch) non spill line blinds that are not limited by the installation space. Due to their size a gear box is provided for both clamping and de-clamping the plate as well as for plate travel. They are designed to incorporate the following benefits:

* Clear and visual indication of open or closed

* Fast operation - between 60 seconds and 3 minutes (size dependent)

* Effective non drip by enclosure on all side except the top

* Ease of maintenance

* Safe Operation

* Compact dimensions

- Man Safe – 100% positive isolation

- Compact design for tight fit applications

- Available in sizes up to 64 inches and ASME 2500#

- Non line spreading design

- Fast operation in less than 60 seconds

- Simple operation – one person, one side, no bolts need to be removed

- Keeps your work space spill free and clean

Fast, Compact and Spill Free

Safety Matters

A line blind is a piping component that enables the user to switch a spectacle plate (or figure of eight) quickly and conveniently. Even when it is enclosed on all sides except the top it is not a valve. Over the years we have been asked if we could enclose the non spill line blind on all sides, including the top. Of course it is possible, but we have always politely declined to do so. The reason for this is that it would not be safe. By enclosing the blind on all sides, we would create an enclosed cavity and thereby lose the ability to have full visual sight of the status of the line blind.

Moreover the medium in the enclosed cavity could lead to an increase in pressure greater than the class of the line blind. This is a result of thermal expansion due to temperature variations between day and night. A line blind's primary use is to ensure the safety of employees working near valves. We therefore believe that it should never be completely enclosed.