Stacey - Line Spreading Blind

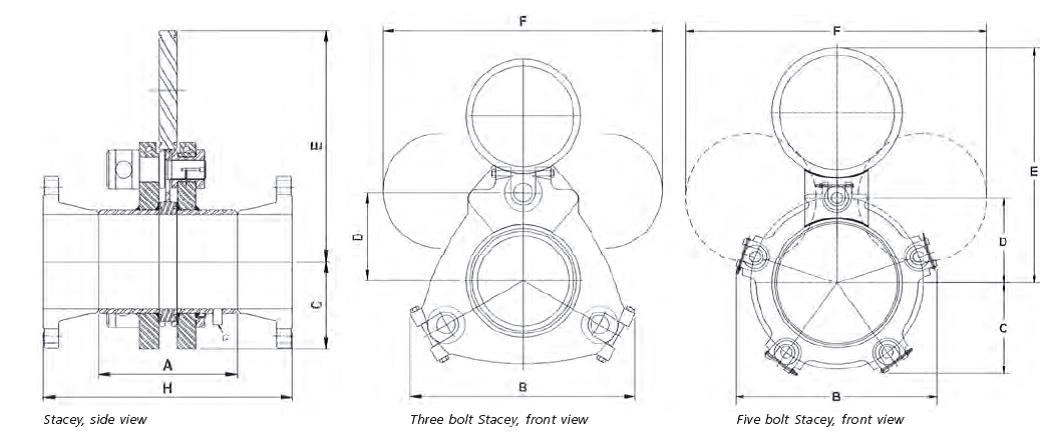

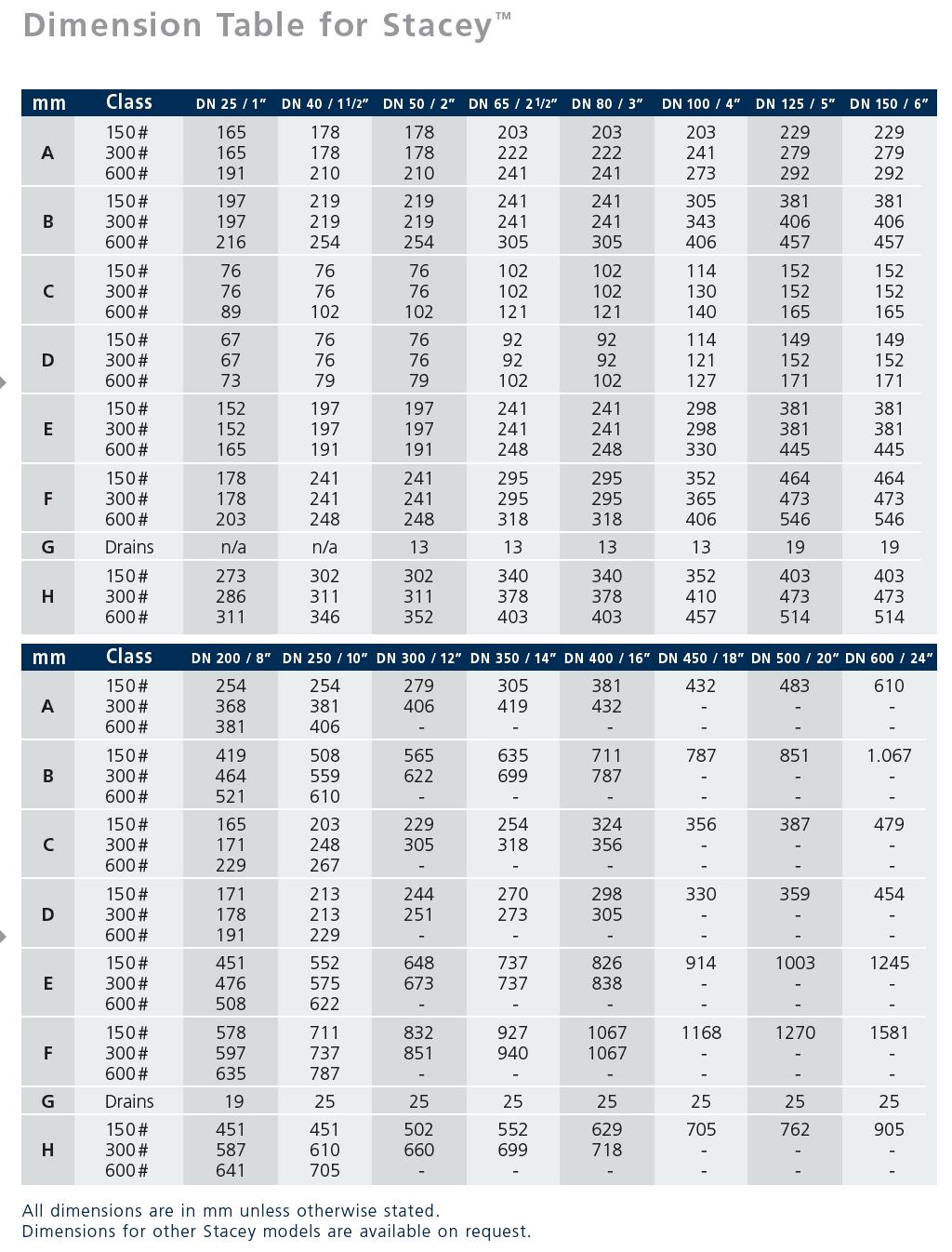

The Stacey (Model 81 FS) is a relatively fast acting line blind that uses spreader bolts to create space to swing the spectacle plate. This feature make the Stacey line blind valve particularly suitable to slurry or applications where there is a scale build up. They are commonly used in the cement, mineral processing and offshore industries.

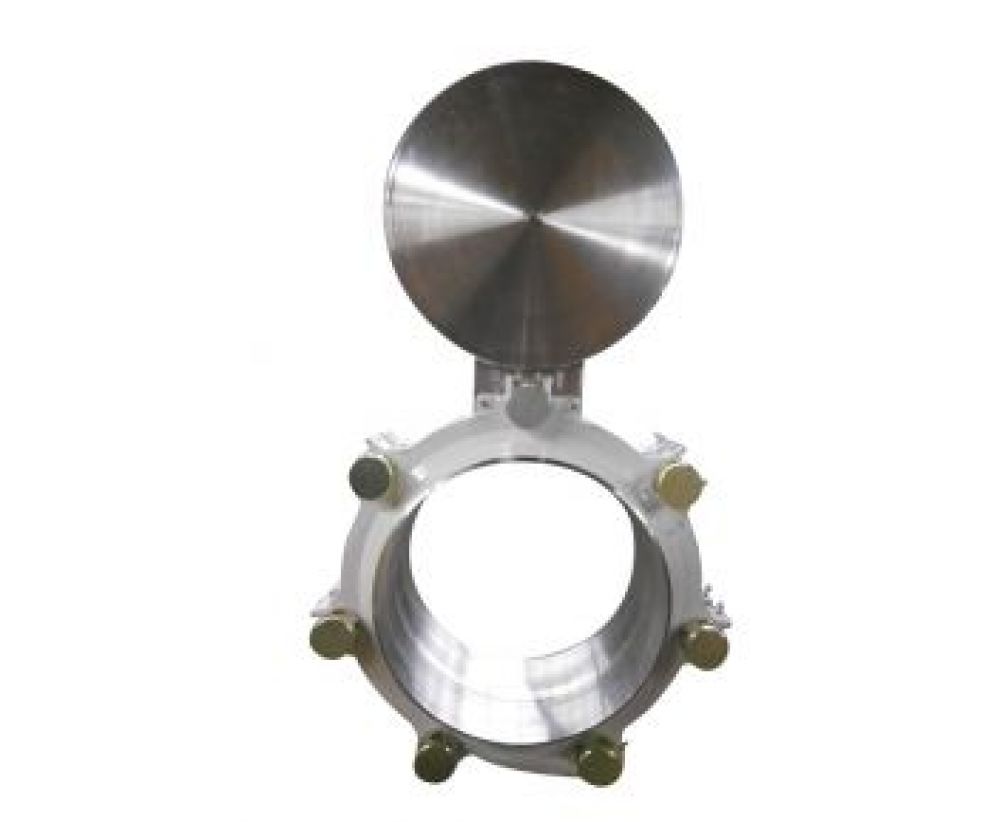

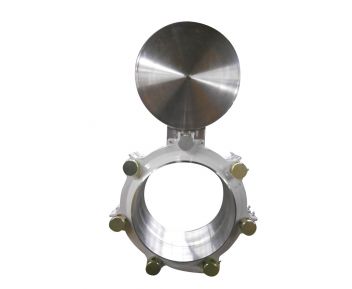

30 inch Stacey - Line spreading blind

30 inch Stacey - Line spreading blind Design & Operation

It has a multi bolt design and a circular body. It is appropriate for applications that require fast blinding turnaround up to 2500# pressure class. It can be made as a standard design up to 54 inches (DN 1600). Its multi bolt design makes for a lighter line blind and one more suitable for higher pressure classes.

With the Stacey blind three bolts (in most sizes) are loosened approximately one turn, automatically spreading the body flanges apart far enough to rotate the spectacle plate to its desired position – full open or closed. Retighten the 3 bolts and the changeover is complete. Bolt heads are drilled to receive a short piece of steel bar or pipe – the only tool required.

- Man Safe – 100% positive isolation

- Line spreading design enables Crust Breaking

- Simple operation – one person, one side, no bolts need to be removed

- Fast operation – less than 2 minutes – size dependent

- Available in sizes up to 64 inches and ASME 2500#

- Conforms to or exceeds many safety and engineering standards

Safe, Robust and Convenient

- A broad range of sealing rings to match the specific medium and operating conditions including the most common – Viton, Kalrez, Aflas, EPR/EPDM, PTFE and Graphite

- Stem and dust covers for powder applications or dusty operating environments

- Lock out devices

- Manual actuation

- Filter or sieve integration in the spectacle plate

- Drain, vent and purge connections

- Special anti corrosive or medium driven coatings or linings (such as Sermetal, Epoxy, PFA or ceramics)